RAGAGEP: What is it, and why does it matter?

The OSHA standard for Process Safety Management (PSM) requires that all equipment, inspections, and testing procedures comply with Recognized And Generally Accepted Good Engineering Practices–RAGAGEP for short.

However, the PSM standard offers little explanation of what exactly RAGAGEP means or what it takes to comply with that requirement. RAGAGEP is as confusing as it is simple, so let’s take a few minutes to break it down and help your facility stay OSHA compliant whether you’re covered by the PSM standard or not.

What is RAGAGEP?

In May 2016, OSHA issued a memo outlining four examples of RAGAGEP–the first two being especially relevant to the ammonia refrigeration industry:

First, there are “widely adopted codes,” such as NFPA 70, The National Electric Code. Codes of this sort have been widely adopted by federal, state, or local governments, and so any buildings constructed in those jurisdictions must be built according to those codes.

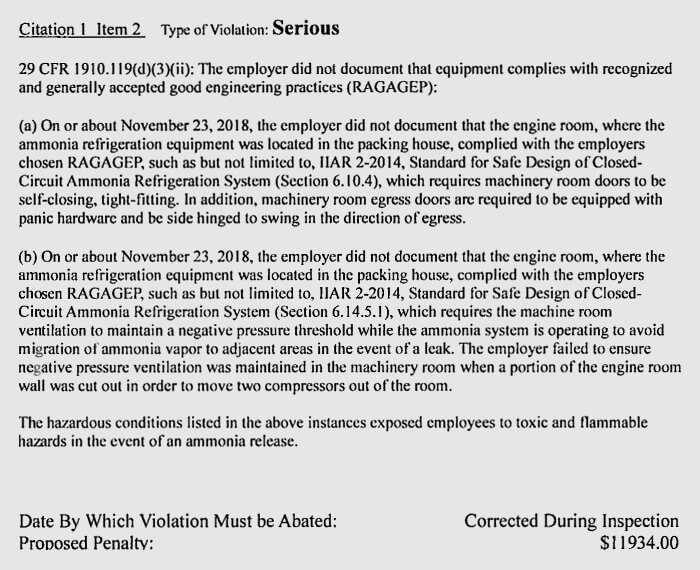

Second are the more industry-specific “consensus documents:” documents which are considered to be “sources of RAGAGEP by those knowledgeable in the industry.” In fact, OSHA specifically mentions the IIAR 2 standard by the International Institute of Ammonia Refrigeration as a consensus document. This means that all design, installation, and maintenance of ammonia refrigeration equipment must comply with the requirements found in that document.

Why does RAGAGEP matter?

That gives us a general understanding of what RAGAGEP is, but why should we care? Because it means that any standards recognized by OSHA as “good engineering practices” (such as those from the IIAR or NFPA) must be followed as if they were law.

These standards must be followed from the design process (IIAR 2) all the way through long-term maintenance of the system (IIAR 6). IIAR standards further cover items like: proper mechanical room signage, emergency stops, relief valves, valve tags, pipe labels, and even methods for testing controls and safety systems.

Because the IIAR standards are considered “good engineering practices,” failure to meet any of them can be cited and fined by an inspector, even though OSHA doesn’t have a specific regulations for ammonia systems.

How to stay compliant

So what can you do the ensure your facility stays compliant with RAGAGEP?

The very first thing is to identify which codes and editions were used in the construction of your refrigeration system. For example, if your facility was built in 2003 to comply with IIAR 2-1999, it would not be required to comply with IIAR 2-2014, provided that the equipment is documented as being “designed, maintained, inspected, tested, and operating in a safe manner.”

Second is to ensure that all inspection and maintenance practices follow existing IIAR standards. A robust Preventative Maintenance (PM) program that follows IIAR standards will identify potential RAGAGEP violations early on, giving you time to correct problems before you are cited by OSHA, saving you time and money.

Beyond being part of OSHA’s PSM regulations, following RAGAGEP just makes sense. IIAR standards are written to ensure the safety, efficiency, and longevity of ammonia systems–the ultimate goal of any well-rounded PSM program.