Tube Ice Maker Project with CO2 Refrigerant

Innovative Refrigeration Systems is a leading design-build contractor headquartered in Lyndhurst, Virginia. Our team of experienced in-house engineers specialize in designing custom refrigeration systems, which are expertly fabricated in our 120,000+ sqft shop. Our Lyndhurst facility is renowned for manufacturing large-scale projects that require ingenuity and creativity.

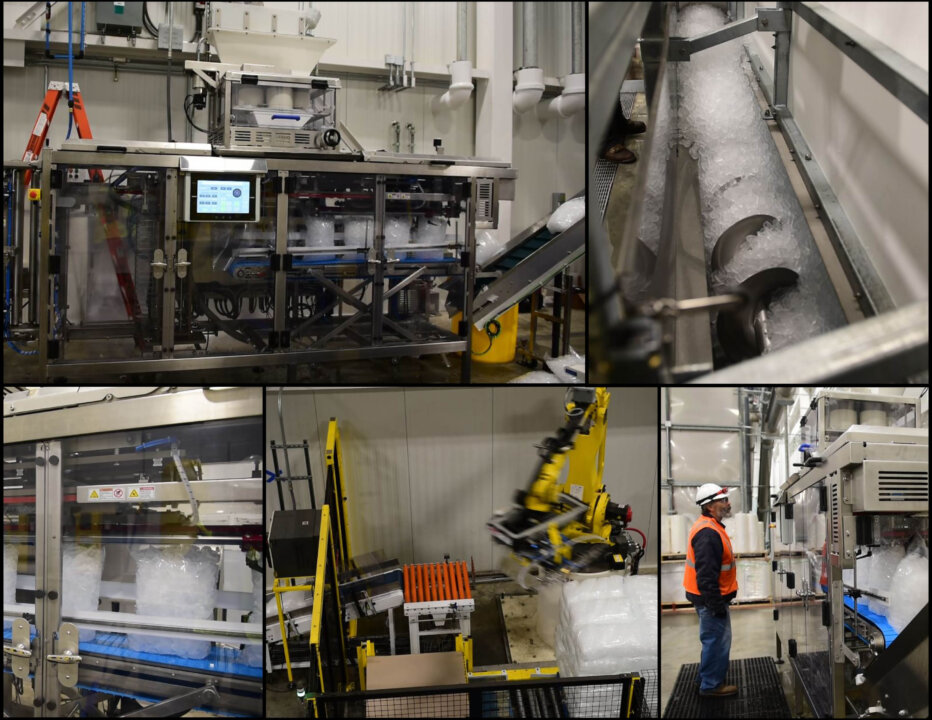

One such project that we successfully completed earlier this year is a two-stage cascade refrigeration system for a tube ice maker in Pennsylvania. Despite the challenges posed by the COVID-19 pandemic and supply chain disruptions, our team worked closely with our partners, the customer, and the general contractor to overcome these obstacles and deliver a high-quality project.

What makes this project unique is that the tube ice makers were specifically designed to work with CO2 as the refrigerant, making them environmentally friendly. Each ice maker is capable of producing an impressive 60 tons per day of tube ice. According to our project manager, this project posed some exciting engineering, design, and control challenges due to the properties of CO2.

At Innovative, we are proud to be a world leader in the engineering, design, and construction of industrial CO2 cascade refrigeration systems. CO2 is a naturally occurring refrigerant that has no ozone depletion potential and is a green refrigerant due to its extremely low Global Warming Potential (GWP) of 1. This is in contrast to most Freons, which have a GWP greater than 3000.

If you’re looking to achieve your refrigeration climate goals, we encourage you to get in touch with our sales team today. Innovative is committed to providing innovative solutions that are effective and environmentally sustainable.